HYDRAULIC POWER & CONTROL UNIT

HYDRAULIC POWER & CONTROL UNIT

Meet Pantera: Power, Control & Versatility

Power, Control & Versatility

BLAC INC. Pantera Series hydraulic power and control unit (HPCU) is designed for both modulating and on-off applications and can be used to provide linear thrust or quarter turn torque.

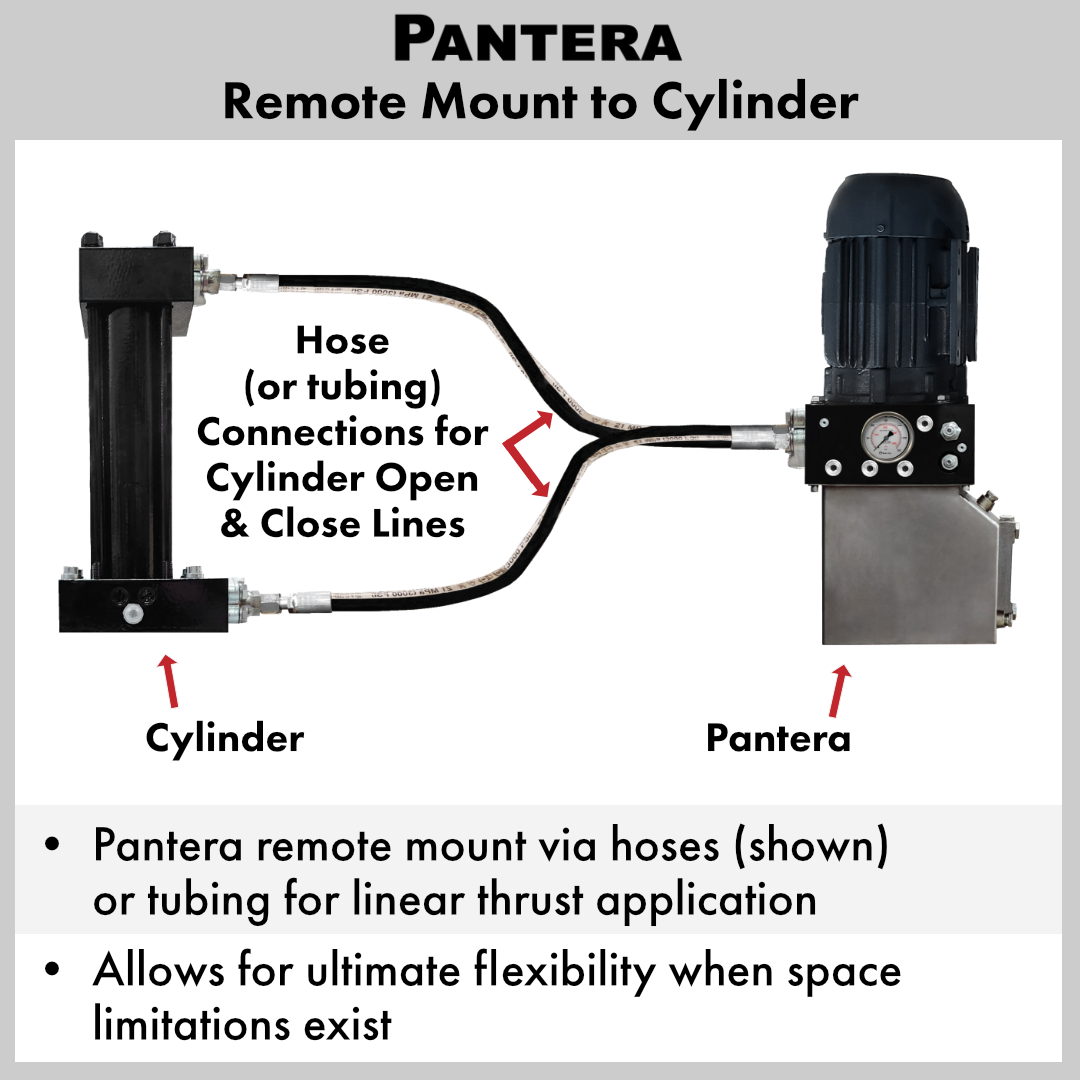

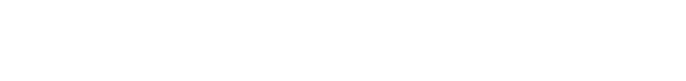

The Pantera HPCU may be mounted directly to the cylinder for a self-contained setup, located remotely via hose or tubing connections to the cylinder, or as a standalone power unit.

Pantera is power and control with the versatility industries demand.

Get Started: Pantera HPCU

The standard Pantera HPCU includes the motor/pump assembly, reservoir, and core control manifold components.

Applications

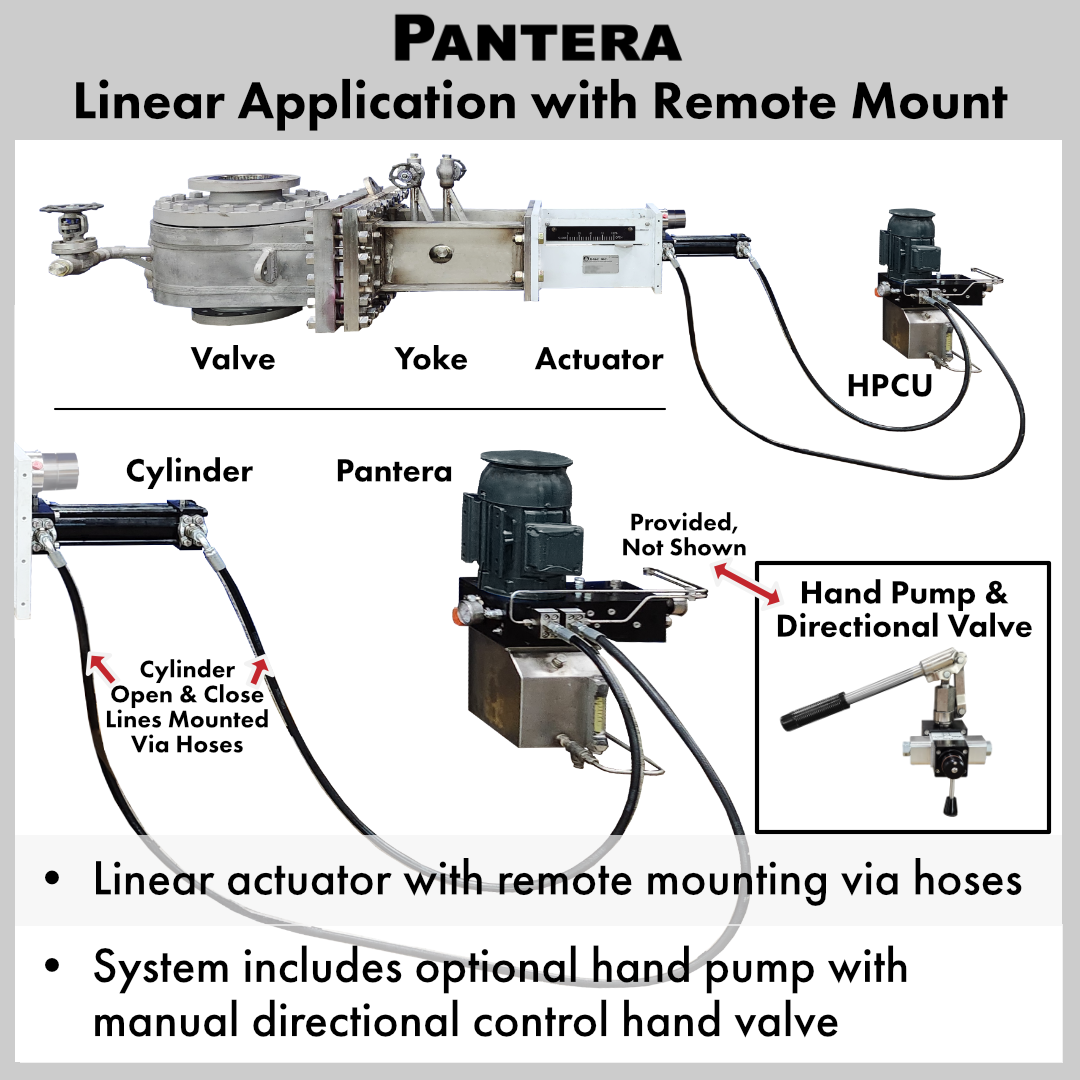

The versatile Pantera design supports use in a wide range of applications and environments. Optional features, including solenoids, accumulators for critical or emergency service, and provisions for hand pump or handwheel operation, can be added to meet specific application needs.

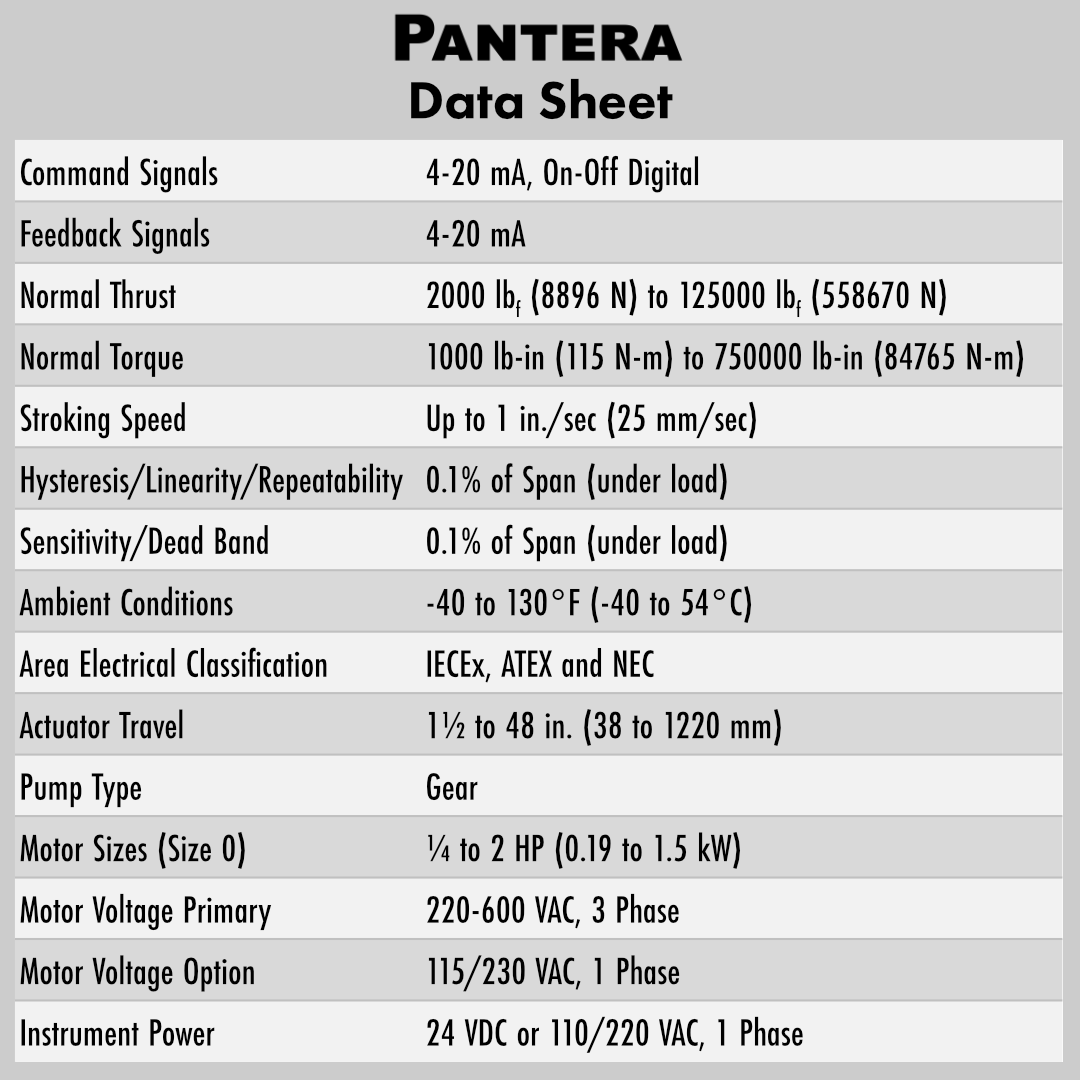

Technical

Technical details for Pantera, including linear thrust and quarter-turn torque sizing, are provided below. For alternate sizes, please contact BLAC INC.